Wheeled Class D Metal Fire Extinguisher - Cartridge Pressure Type

V-Safe brand Class D fire extinguishers are applicable on reactive metal fires with application area in power plants, battery manufacturing units, explosive industries, nuclear power plants, metallurgical plants, pharmaceuticals and chemical plants as well as units handling flammable metals in aggressive state.

Sodium chloride based agent is applicable on metal fire of Mg, Al powders & paste, Ti, Fe and their alloys with spills and in depth fire source.

Ternary Eutectic Chloride (TEC) based agent is applicable on fire lithium and its alloys mainly used in batteries and other such applications.

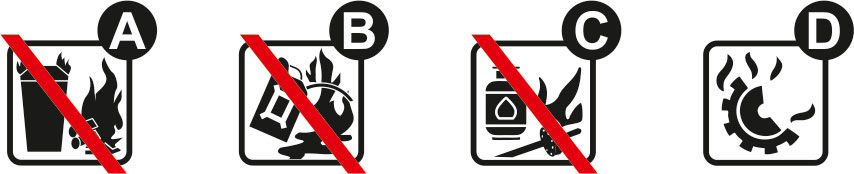

Suitable Classess of Fire :

Certifications :

Capacity :

Features :

- Easy to operate & maintain

- Specially designed extension diffusers for soft flow to fight aggressive metal fires

- Applicable on Li-ion battery fire

- Cartridge Pressure type, hence always ready for action

Model Codes & Technical Specifications

| Capacity | Model | Agent | Propellant | Gross Weight (kg) | Working Pressure (Bar) | Discharge Time (sec) | Operating Temperature |

|---|---|---|---|---|---|---|---|

| 25 kg | VFMPQ-25 | TEC / Sodium Chloride | Regulated N₂ cylinder | 83.0 | 17 | 25 | -30° C to +55° C |

| 50 kg | VFMPQ-50 | 118.0 | 17 | 25 | |||

| 75 kg | VFMPQ-75 | 149.0 | 17 | 25 |